PRODUCTS

FOUR REASONS TO CHOOSE US

AAA Level

Credit Steel Supplier

10+

Stock Warehouses

Support

Three-party Inspection

Large Order

Preferential Policies

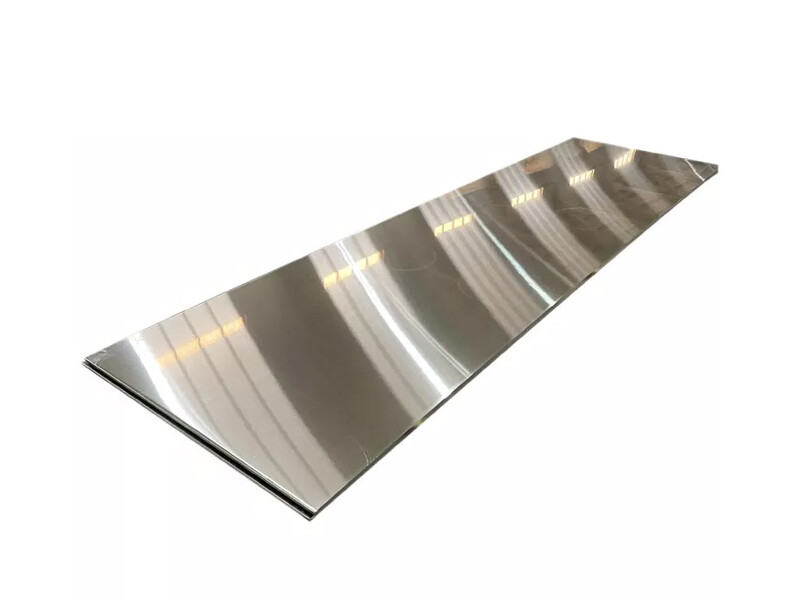

Tin plating has been widely used in the electronic industry as a protective and solderable coating for electronic components, wires, printed circuit boards, and integrated circuit blocks due to its excellent corrosion resistance and solderability.

The application of electroplated tin is very extensive. Tin has advantages such as corrosion resistance, color resistance, non toxicity, easy brazing, softness, low melting point, and good ductility. Through special pre-treatment processes, a strong, bright, dense, uniform, and continuous alloy coating is formed on the surface of composite materials.

Product Parameters

Surface State of Tinplate

Substrate Type

Coating Weight

Chemical Composition

Mechanical Properties & Applications

Ordering Notes

The ordering elements for tin plating generally include: standard grade (including steel grade code, annealing method and other information such as MR T-3 CA), size (the default order is thickness * width * length, tin plating amount ((different thickness plating) Tin needs to add A/D as the marking line mark, if not, no marking line will be marked), surface, order quantity, etc.

When ordering tin plating, please confirm with our sales staff the end use, such as canbody, ends, twist off caps, crown cork, EOE, etc., as well as the contents, special contents such as milk powder, high protein food, mushrooms, fruits, etc.;

Related Products

Leave Your Message

Consulting Bulk Order Discounts

Jiancheng Steel is committed to providing the most reliable and satisfactory steel and metal product solutions to global users.