PRODUCTS

FOUR REASONS TO CHOOSE US

AAA Level

Credit Steel Supplier

10+

Stock Warehouses

Support

Three-party Inspection

Large Order

Preferential Policies

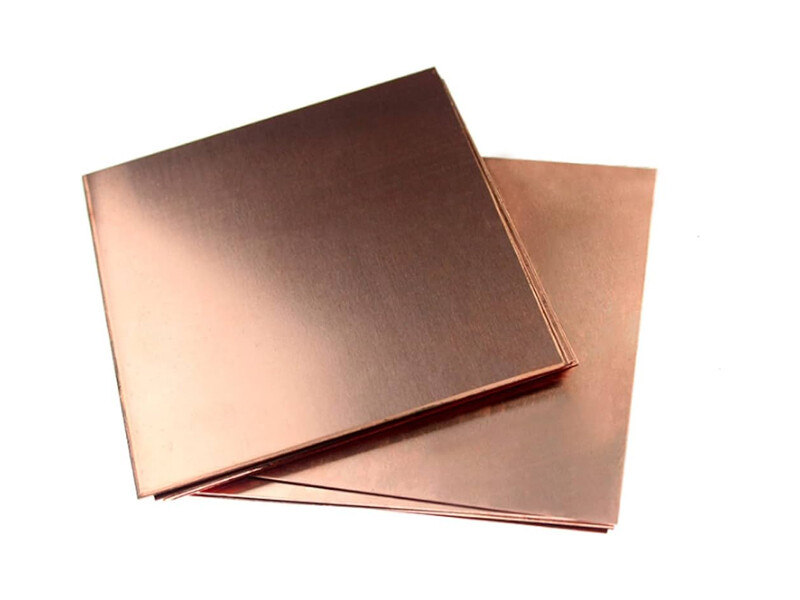

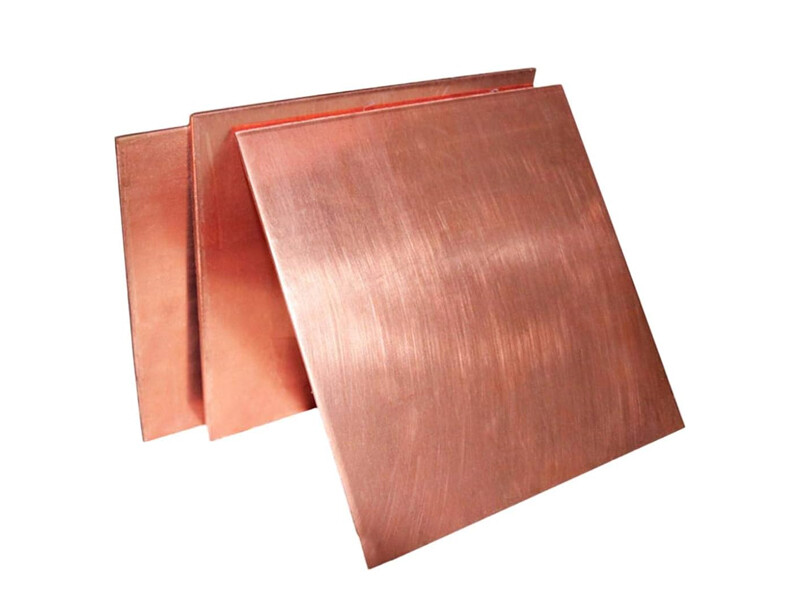

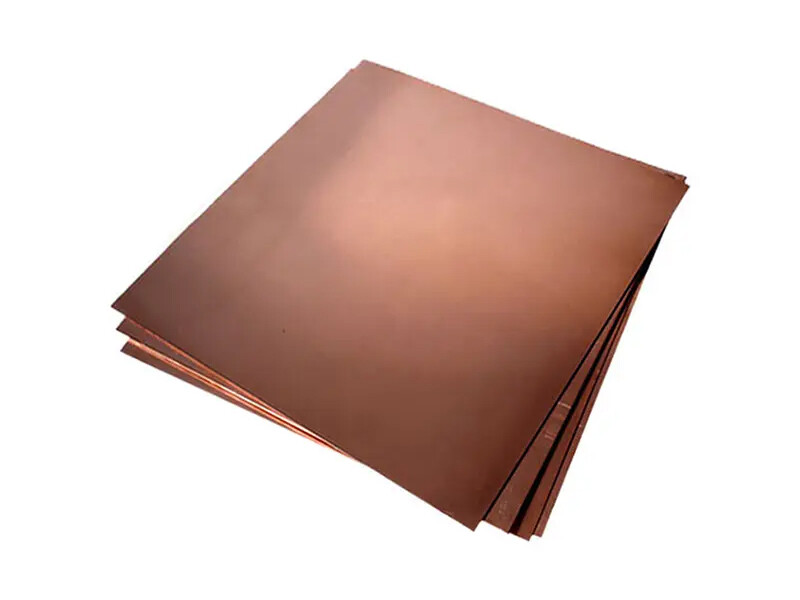

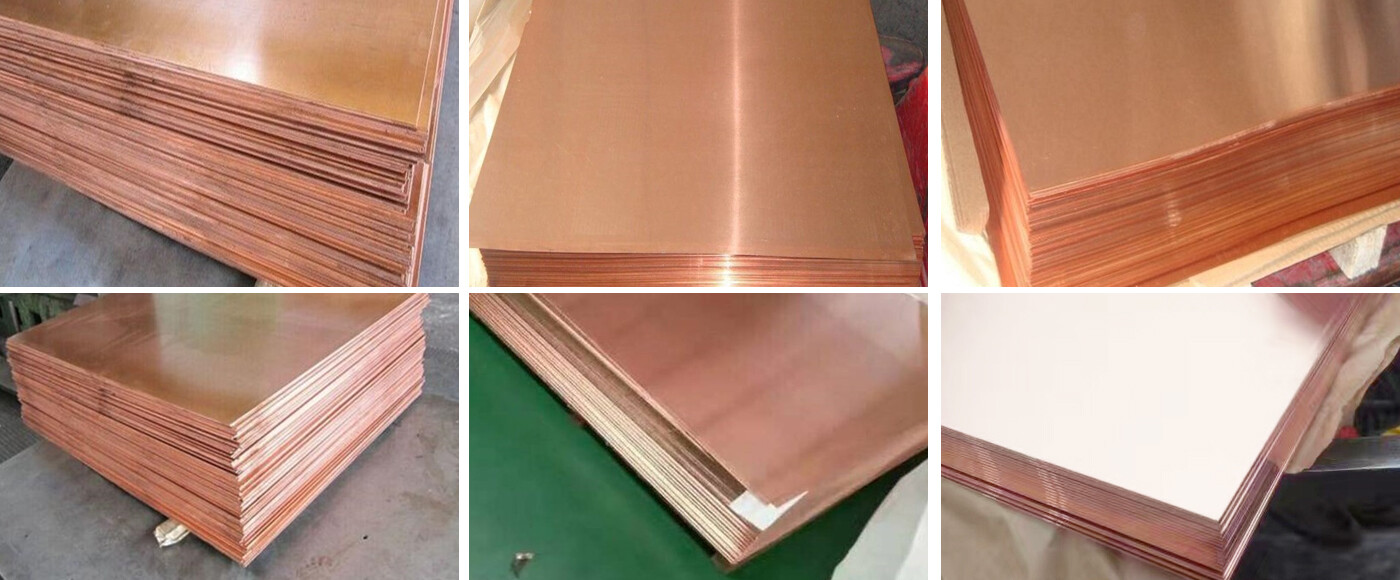

C24000 copper plate has excellent machinability and is suitable for a variety of manufacturing processes, including but not limited to stamping, drawing, bending and forging. This alloy has a low hardening rate during machining, allowing multiple cold workings without intermediate annealing. Besides, C24000 copper plate shows good corrosion resistance in a variety of environments, especially in dry atmospheres. C24000 copper plate is particularly suitable for cold and hot working and can be made into a variety of complex shapes and structures, making it an ideal choice for decoration, construction and some industrial applications. At the same time, it will continue to be widely adopted around the world as a cost-effective and reliable material.

Product Parameters

APPLICATIONS &INDUSTRIES

Shipping News

Related Products

Leave Your Message

Consulting Bulk Order Discounts

Jiancheng Steel is committed to providing the most reliable and satisfactory steel and metal product solutions to global users.