PRODUCTS

FOUR REASONS TO CHOOSE US

AAA Level

Credit Steel Supplier

10+

Stock Warehouses

Support

Three-party Inspection

Large Order

Preferential Policies

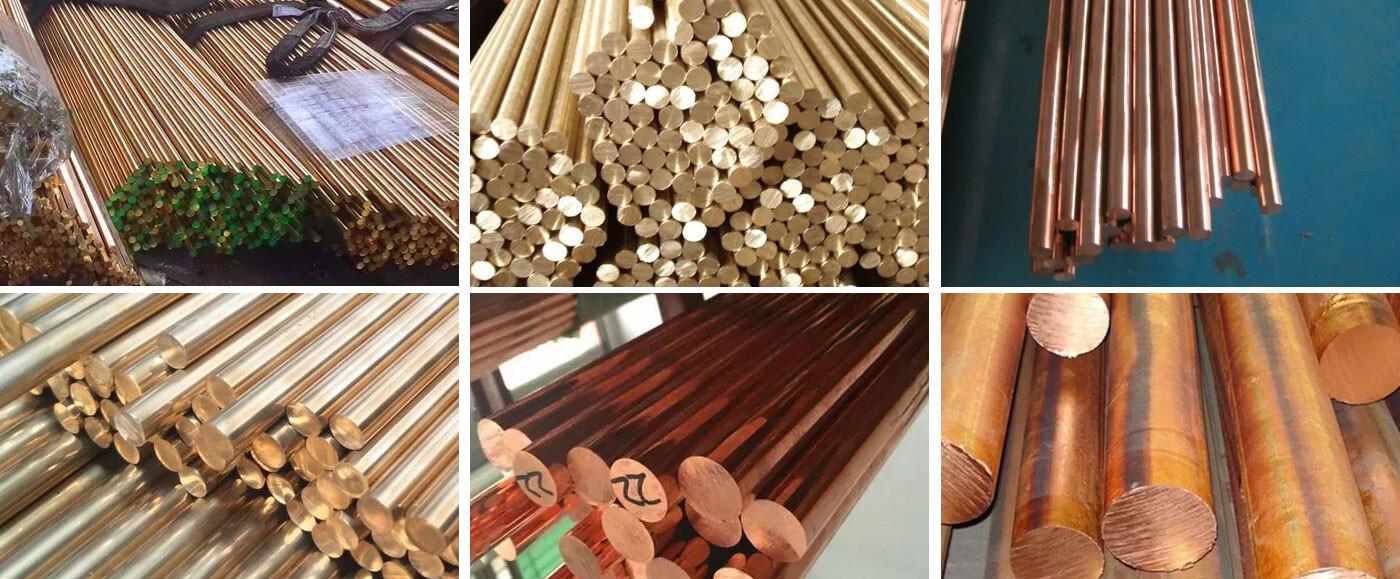

C23000 copper bar is characterized by excellent formability, corrosion resistance, and high strength, while maintaining the good electrical and thermal conductivity unique to copper alloys. The bar shows good corrosion resistance in most environments, especially to the atmosphere, water, and some chemicals. Besides, C23000 copper bar has higher strength compared to other commercial coppers, making it suitable for structural applications that can withstand certain loads. Good processability allows it to be processed and formed by conventional metal processing techniques.The properties of C23000 copper bar make it very popular in a variety of applications, especially in the decorative and architectural fields.

Product Parameters

APPLICATIONS &INDUSTRIES

Shipping News

Related Products

Leave Your Message

Consulting Bulk Order Discounts

Jiancheng Steel is committed to providing the most reliable and satisfactory steel and metal product solutions to global users.