PRODUCTS

FOUR REASONS TO CHOOSE US

AAA Level

Credit Steel Supplier

10+

Stock Warehouses

Support

Three-party Inspection

Large Order

Preferential Policies

Inconel 718 is known for being a high-strength, high-temperature, corrosion-resistant nickel-based alloy whose chemical composition includes elements such as nickel, chromium, molybdenum, iron, cobalt, aluminum, titanium, zirconium, carbon, and manganese. Inconel 718 pipe has a melting point of 1430°C and displays effective heat and temperature resistance. It also works well at low temperatures. This nickel superalloy has the inherent ability to create a strong and stable oxide layer when heated. In addition, the layer makes this Inconel variant significantly resistant to oxidation, thus protecting it from corrosion. Inconel 718 pipe can be manufactured through a variety of processing methods, such as forging, hot rolling, cold drawing and welding. One thing to keep in mind is it is prone to oxidation and hardening at high temperatures, and appropriate preheating and post-processing measures are necessary to reduce this phenomenon.

Product Parameters

APPLICATIONS &INDUSTRIES

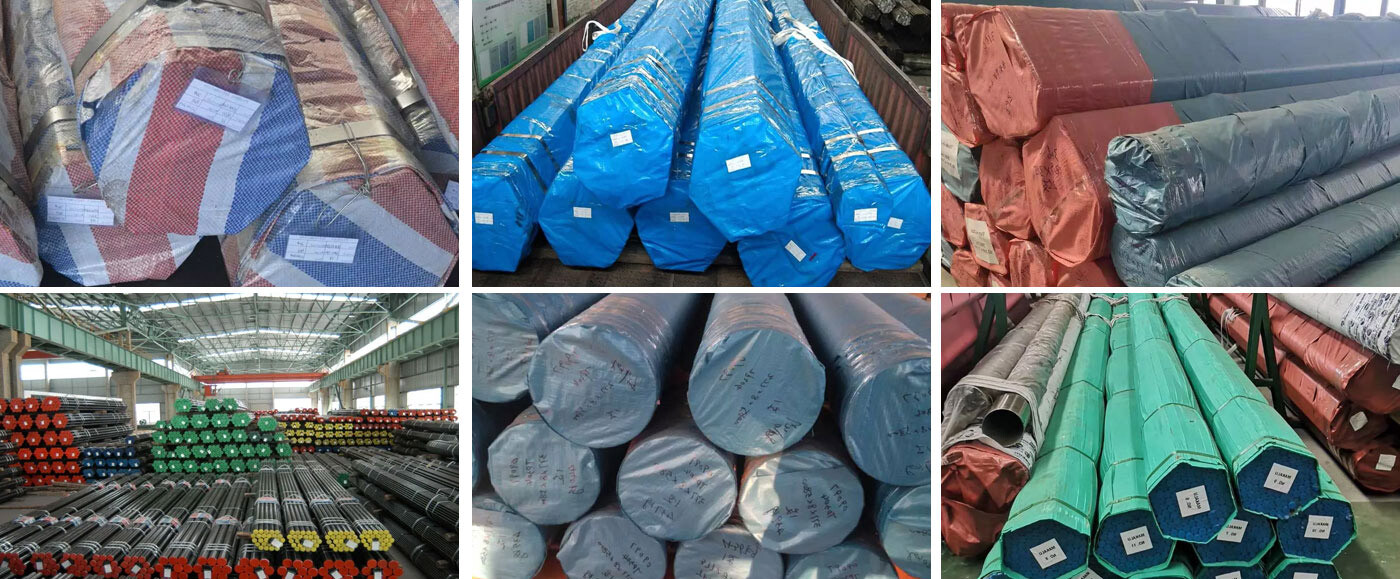

Shipping News

Related Products

Leave Your Message

Consulting Bulk Order Discounts

Jiancheng Steel is committed to providing the most reliable and satisfactory steel and metal product solutions to global users.